New low-friction, high efficiency engines made possible by the patented J-Clutch

X

X

X

X

X

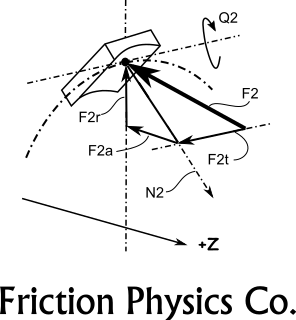

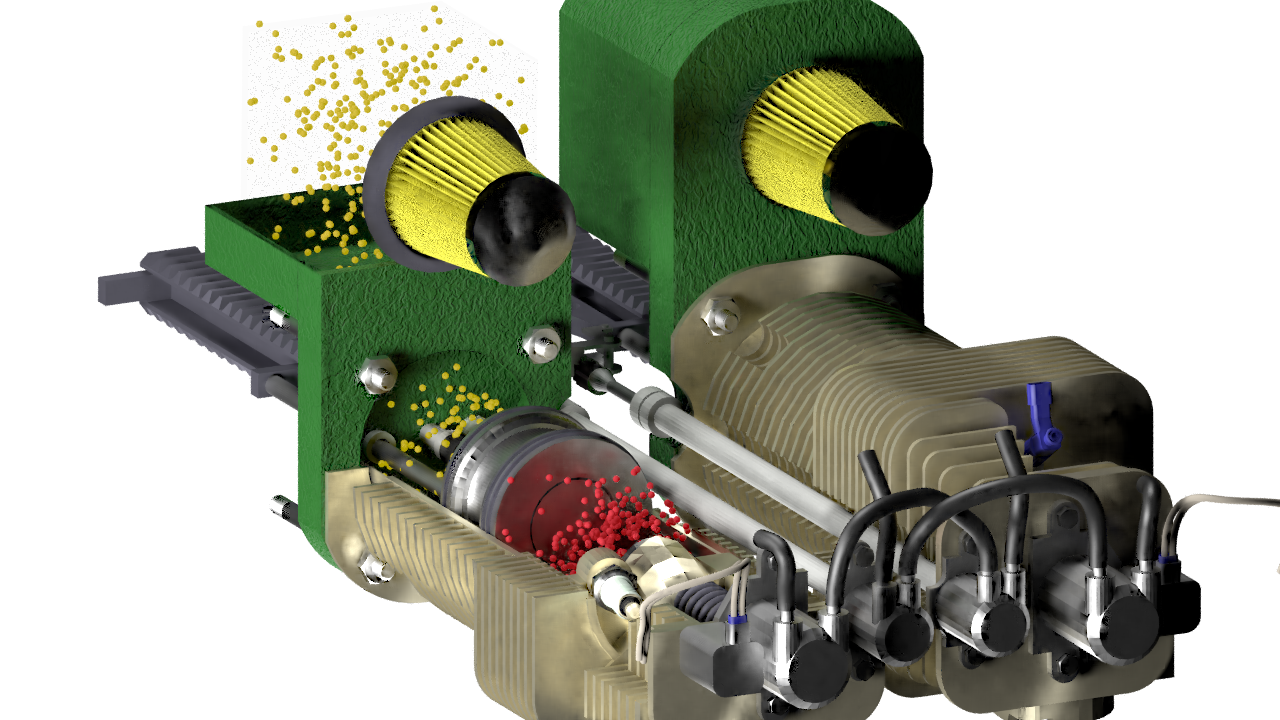

The J-Drive engine is an innovative internal combustion engine design made possible by Friction Physics' patented J-Clutch. The rugged and durable J-Clutch replaces the crankshaft with a rack-and-pinion power linkage named the J-Drive. After years of engineering and computer modeling J-Drive engines are ready for prototyping. Note that the technology disclosed here is protected by United States and international patents, both granted and pending.

The Model J-10 is suited for trucking, marine and construction applications. Performance characteristics are similar to the boxer type, J9. Four cylinder models are shown here. Two cylinder, six cylinder, eight cylinder+ configurations are straight forward implementations.

Boxer Model J-9, aircraft configuration

Page Contents

- 1Specifications

- 2Videos and Charts

Specifications and Thermodynamics

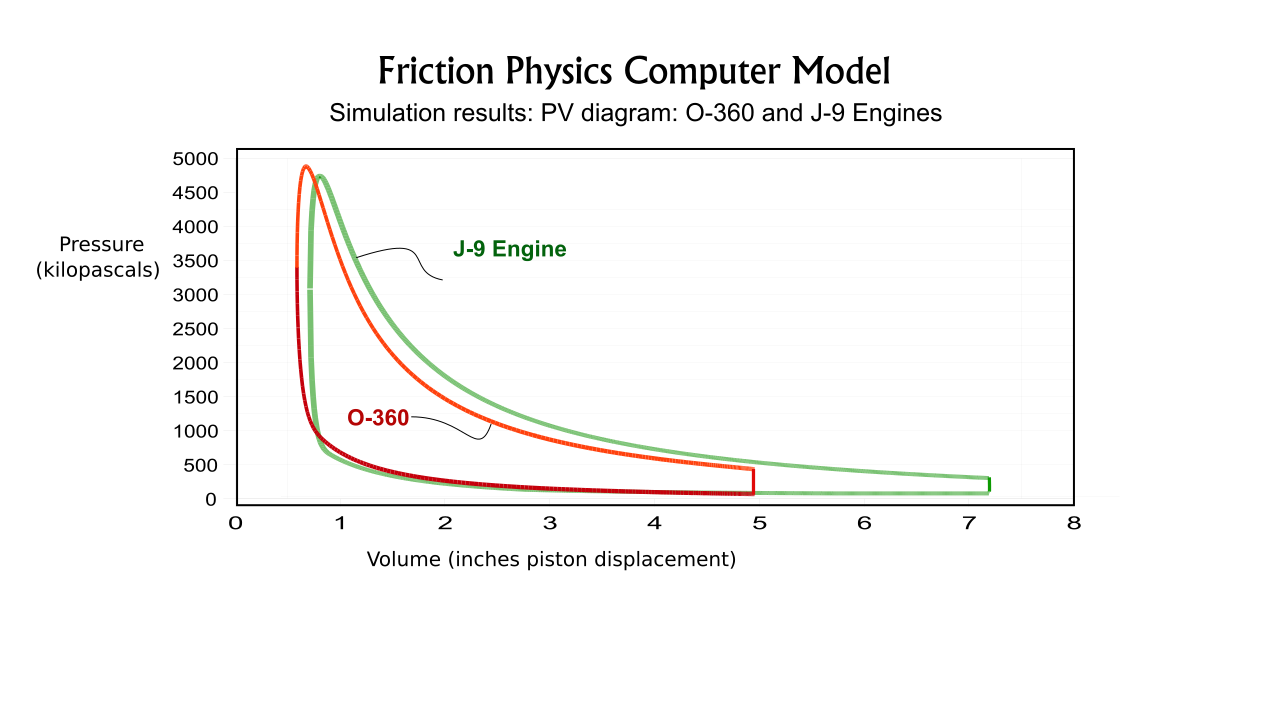

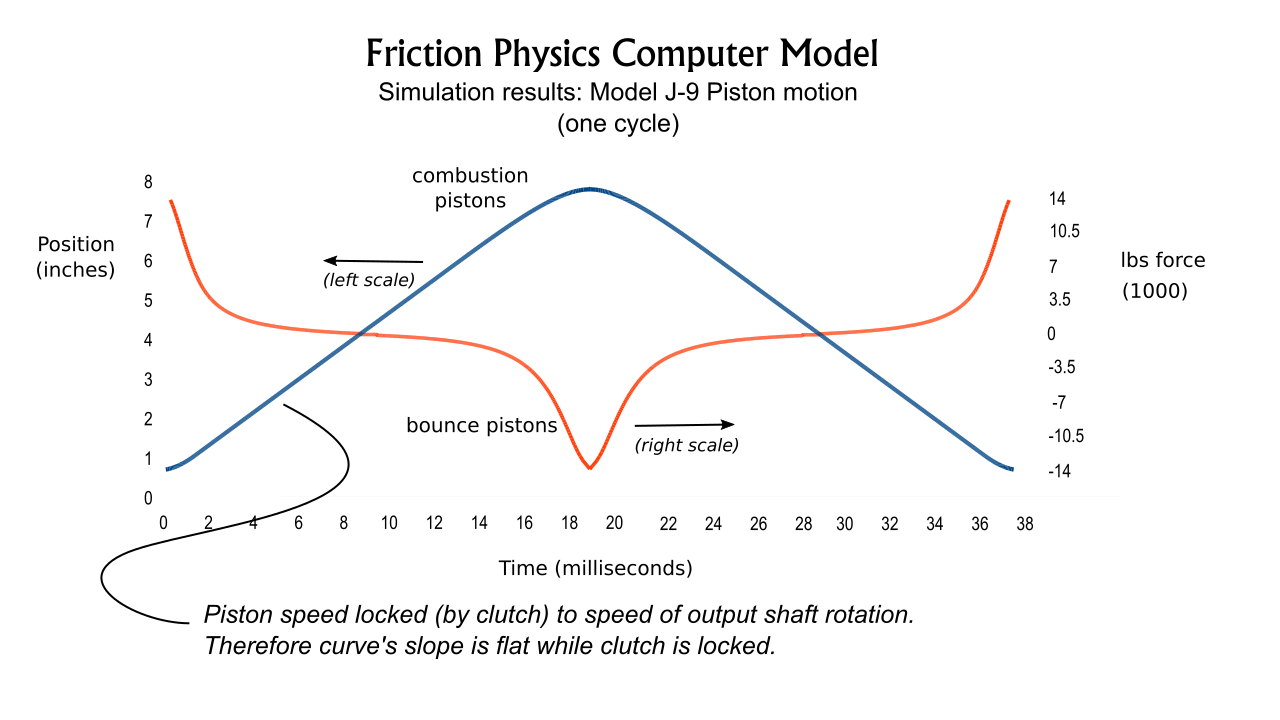

Friction Physics developed a detailed computer engine model that was proofed against standard aircraft engine performance. The Lycoming O-360 A1A was chosen to represent the current state of technology. Extensive performance data for the O-360 are available. After validation of the computer model against the O-360, Friction Physics presents simulation results for the model J-9 engine.

J-Drive engines provide:

- greater fuel efficiency

- greater power

- far cooler operation

- lower manufacturing cost

Model J-9 Dimensions vs. O-360

| Characteristic | O-360 Simulation | O-360 Published | Model J-9 | notes |

|---|---|---|---|---|

| bore | 5.125 in | 5.125 in | 5.125 in | combustion cylinder/piston diameter |

| displacement | 361 cu-in | 361 cu-in | 506 cu-in | For Model J-9, displacement is volume of chamber when valves close, not a measure of piston sweep |

| compression stroke | 4.375 in | 4.375 in | 5.3 in | |

| power stroke | 4.375 in | 4.375 in | 6.24 in | J-Drive extended power stroke |

| Compression Ratio | 8.5 : 1 | 8.5 : 1 | 7 : 1 | |

| Fuel Type | AVGAS 100LL | automotive | ||

| percent Atkinson | 0 | 0 | 26% | by volume |

| weight | 258 lbs | ~370 lbs | ||

| power to weight ratio | 0.7 HP/lb | ~0.7 HP/lb |

Full Power, Sea Level Performance

| Characteristic | O-360 Simulation | O-360 Published | Model J-9 | notes |

|---|---|---|---|---|

| Power | 180 HP | 180 HP | 260 HP | |

| Fuel Rate | 16.2 gal/hr | 15-16 gal/hr | 15 gal/hr | |

| HP per (gal/hr) rate | 10.8 HP/gal | ~11.2 HP/gal | 18 HP/gal | inverse of gal/HP |

| EGT | 1440 °F | 1300 to 1400 °F | 1215 °F | Exhaust Gas Temp. |

| CHT | 363 °F | 350 to 435 °F | 331 °F | Cylinder Head Temp. |

| Engine Speed | 2700 RPM | 2700 RPM | 1625 Cycles/min | |

| power strokes/min | 5400 | 5400 | 6500 | |

| mixture (Φ) | 1.4 | "full rich" | 0.65 | mixture equivalency ratio (ϕ) |

| Air/Fuel ratio | 10.5 | - | 22.6 | 14.7 is stoichiometric |

| % fuel energy to shaft | 25.3% | - | 40% | fuel conversion efficiency |

| % burned fuel energy to exhaust | 46.6% | 44% | 45% | heat energy in expelled exhaust gas |

| power to engine heat | 64 kilowatts | - | 60 kilowatts | friction and conduction |

| BMEP | 1012 kPa | - | 815 kPa | Brake Mean Effective Pressure |

75% Power Cruise at 5000 feet altitude

| Characteristic | O-360 Simulation | O-360 Published | Model J-9 | notes |

|---|---|---|---|---|

| Power | 135 HP | 135 HP | 190 HP | |

| Fuel Rate | 9.8 gal/hr | 9.5-10 gal/hr | 11 gal/hr | |

| HP per (gal/hr) rate | 13.75 HP/gal | 17.6 HP/gal | inverse of gal/HP | |

| EGT | 1406 °F | 1350 to 1450 °F | 1000 °F | Exhaust Gas Temp. |

| CHT | 353 °F | 350 to 435 °F | 275 °F | Cylinder Head Temp. |

| Engine Speed | 2400 RPM | 2400 RPM | 1610 Cycles/min | |

| mixture (Φ) | 1.1 | rich of peak | 0.55 | mixture equivalency ratio (ϕ) |

| Air/Fuel ratio | 13.36 | - | 26.7 | 14.7 is stoichiometric |

| % fuel energy to shaft | 31.2% | 29-30% | 41% | fuel conversion efficiency |

| % fuel energy to exhaust | 43% | 44% | 42% | heat energy in expelled exhaust gas |

| power to engine heat | 63 kilowatts | - | 51 kilowatts | friction and conduction |

| BMEP | 850 kPa | - | 598 kPa | Brake Mean Effective Pressure |